|

Remember the Old Fanning Mill?

by

Very much a part of a museum collection these days seems to be the fanning

mill. They were as much a part of the farm of the old days as the old

oaken bucket. At least a few years ago, it could be found sitting forlornly

in back of the barn, long since forgotten by the present generation. When

I lived on a farm in the 1950s, we also had one stored in back of the

granary, with seemingly 50 years of dust on it. I used to like to crank

it, and always wondered what it was used for. I was told, "Oh, that's

just an old thing we used to separate grain."

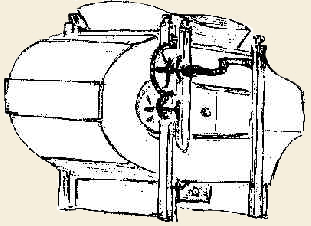

A fanning mill is a peculiar-looking device made of wood, with a metal

crank and wooden hand grip, and with sliding drawers, rounded board edges,

shaped carrying handles, and sometimes lathe-turned knobs atop the frame

posts, appearing almost like a piece of furniture. Like other old-time

machinery, fanning mills were attractively painted in gaudy colors which,

by this time, have long since faded away. But when restored to their natural

beauty, they are quite attractive.

Fanning mills removed straw, chaff, stones, dirt and dust, weed seeds,

and light immature seeds from wheat, oats, rye, barley, and other grains.

It was important to remove contaminants for better preservation during

storage, to have mold and grit free flour, and for securing viable seed

free of weed seeds that would compete with a growing cereal crop. Fanning

mills were a great technical advance over winnowing, the hand-process

of pouring grain from one container to another in a breeze to blow away

the lighter matter.

In many ways, a fanning mill resembles a miniature threshing machine.

Both machines have shaking sieves over which the threshed grain kernels

mixed with bits of straw, chaff, stones and soil particles rattle. The

smaller pieces fall through holes to a lower sieve where smaller particles

are separated. Both machines have fans that move air across and upward

through the sieves to float off the light straw, chaff and dust. Only

the threshing machine has a mechanism for knocking the grain kernels free

of their attachment to the grain stalk.

Before the introduction of threshing machines, grain was removed from

the stalk heads by trampling or flailing. This operation was done usually

on a wooden floor in a barn. Threshing barns were built for the purpose

of storing grain sheaves from harvest time until the slack winter season

when the fully mature grain could be separated from the dry straw. These

barns were built around a central threshing floor where the bundles of

ripened grain could be spread to a uniform thickness and treaded upon

by hooves of horses or oxen or pounded by farm hands using wooden flails

to loosen grain kernels from heads of the cereal plant stalks.

When most of the kernels had been loosened from the grain heads, the

straw was lifted off with forks and stored for use as bedding for livestock.

The remaining material on the threshing floor was scooped up to be winnowed

when there was a breeze. Threshing barns usually had wide doors which

could be opened at either end of the center section to allow a favorable

wind to waft through the building. The chaff, bits of straw and the loose

grain from the threshing floor were put in a winnowing basket or tray

and tossed upward into a breeze where currents of air carried the straw

pieces, lighter chaff and dust farther away, as the heavier kernels of

grain fell more directly downward into a basket or onto a blanket.

Flailing and winnowing are strenuous tasks. It has been estimated that,

using a flail, one person could separate only seven bushels of grain per

day. Separating kernels of grain from chaff and stalks was a labor-intensive

manual procedure, and careful attention was required to extract the maximum

amount of good grain from the material left on the threshing floor after

flailing and trampling. To ease the arduous work and relieve the monotony,

threshing became a shared neighborly work project and a social activity

that continued on when farmers went from farm to farm with their wagons

to help each other gather shocks to feed into a threshing machine. Commonly

called "a separator" and mounted on wheels, it was moved from farm to

farm. All the cooperating farmers in a circuit made up a "threshing ring."

A fanning mill did a much more efficient job than winnowing, and it cleaned

grain more thoroughly than a threshing machine. Mills were kept around

farms for a long time to reclean oats and wheat in the spring for planting.

|